Wonder Gel and Derustit SS-3 Recommended by Professional Engineer, Walter J. Sperko

Years ago, Walter J. Sperko published a paper explaining why red rust stains appear on stainless steel from carbon steel and moisture in the atmosphere. Mr. Sperko has recently published a follow-up paper with his recommendations for removing such stains. The products he reviewed are our very own Bradford Derustit Wonder Gel Stainless Steel Pickling Gel as well as our Derustit SS-3 Stainless Steel Cleaner for the removal of such stains.

Below, we've highlighted the results of the testing performed and the recommendations for various applications. For the full review and white paper, click the link below:

Evaluation of Wonder Gel™ Stainless Steel Pickling Gel and Derustit SS-3™ Stainless Steel Cleaner

Fig. 1

The photograph shows a 2 inch schedule 10 pipe butt weld made using automatic GTAW (i.e, Orbital TIG) after cleaning with Wonder Gel™. The cleaned surface is lightly etched where the oxides were present leaving a light shadow, but the surfaces are free of any oxides.

Fig. 2

The photograph on the left side shows a section of pipe 0.104 inches thick that was welded using SMAW (i.e., ordinary stick welding); the right side was welded with GTAW before and after cleaning one time with Wonder Gel. The SMAW weld has some small flecks of oxide associated with surface irregularities and small porosity on the surface, and the GTAW weld is almost perfectly clean except for some small dots that are trapped in some shallow surface porosity.

Fig. 3

These welds had a thicker oxide due to the slower cooling rate caused by the comparative thinness of the material, and that made it more difficult for the Wonder Gel to remove in one application. This photograph shows the result after cleaning most of the weld lengths one time with Wonder Gel. The material was 0.107 inches thick. The lower weld was made after the upper weld, so the plate was hotter when making the lower weld than it was when making the upper weld. As a result, the weld pushed through a little starting at the arrow and going rightward. That portion of the weld was near the melting point of the metal, about 2600°F while the weld was being made.

Fig. 4

The photo shows the arc strike shown in the first photograph and partially visible in the second photo. The second photograph shows what it looked like after being cleaned with Wonder Gel. Not unexpectedly, arc strikes were not removed by Wonder Gel; they should be removed by grinding before cleaning with Wonder Gel.

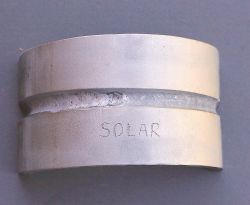

Fig. 5

The first photograph shows the OD surface of a weld that was made using Solar Flux in lieu of inert gas backing of the root side. The second photograph shows the root side. Note the roughness of the root weld metal.

Fig. 6

The next photos show the pipe section after immersion in Derustit SS-3 for 4 hours. On the face side photo, the weld is clean except for some residual oxides trapped in shallow undercut. In the root side photo, oxides are trapped in the surface roughness crevices.

We would like to thank Mr. Sperko for his thorough review of our products, especially of the various types of welds and mechanisms used.

For more information about our line of Derustit products for passivation and pickling of stainless steel, please visit our product page.